Our Customer Service Reps will make sure your hinge is customized to meet your specific needs, at the highest quality, and with the shortest lead times. We can build customer-specific tooling and provide signature services including free parts development, free prototype samples and free inventory management for custom continuous hinge orders. For more information on ordering custom continuous hinges, download our

Product and Service Guide and Capabilities Sheet.

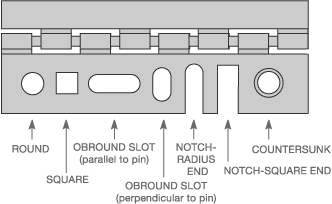

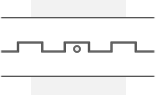

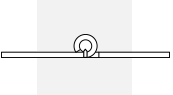

One leaf swaged the full diameter of pin. Leaves are parallel in the closed position.

One leaf swaged one half of pin diameter.

Both leaves swaged one half of pin diameter, with minimum clearance between hinge leaves when parallel.

One leaf swaged to simulate reverse assembly. Leaves do not close to a parallel position.